Engineering plastic modification refers to enhancing the strength, impact resistance, and flame retardancy of regular plastics through filling and compounding processes.

-Reinforcement-

Adding fibrous or plate-like materials such as glass fiber, carbon fiber, and mica powder to plastics to improve their rigidity and strength. For example, glass fiber-reinforced nylon.

-Toughening-

Adding materials such as rubber and thermoplastic elastomers to plastics to improve their toughness and impact strength. Toughened polypropylene is commonly used in automotive, household appliance, and industrial applications.

-Compounding-

Uniformly mixing two or more incompatible polymers into a mixture of macroscopic compatibility or microscopic phase separation to meet the requirements of physical and mechanical properties, optical properties, processing performance, etc.

-Alloying-

Similar to compounding, but with well-compatible components like PC/ABS or PS-modified PPO. It is easy to form a homogeneous system and gain certain functions that is infeasible by a single component.

-Filling-

Improving physical and mechanical properties or reducing costs by adding fillers to plastics.

-Other modifications-

Such as using conductive fillers to reduce the electrical resistivity of plastics; adding antioxidants/light stabilizers to improve the weatherability of materials; adding pigments/dyes to change the color of the material; adding internal/external lubricants to improve the processing performance of the material; using nucleating agents to alter the crystallization characteristics of semi-crystalline plastics to improve their mechanical and optical properties, and so on.

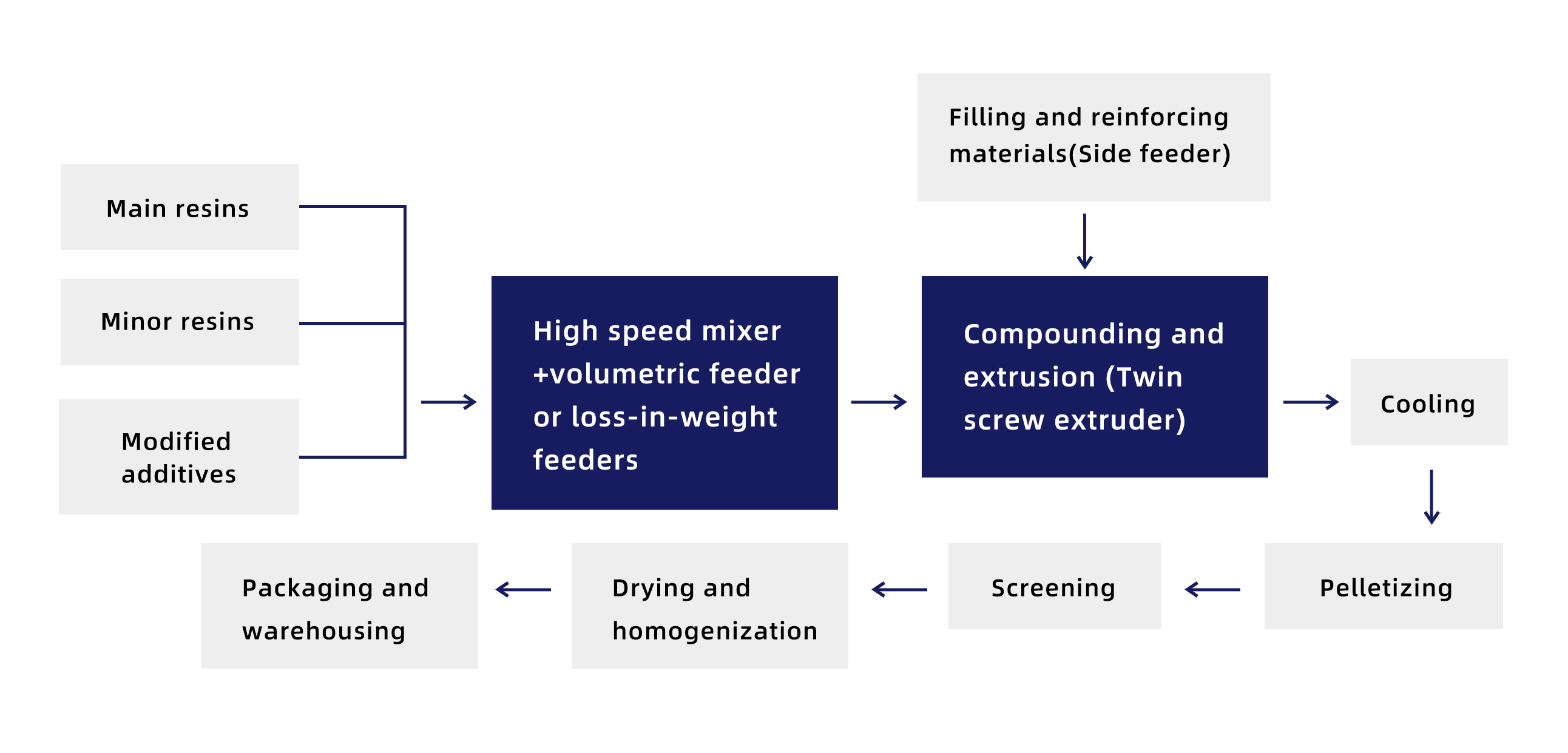

1-Feed raw materials into the twin-screw extruder proportionally using loss-in-weight feeders.

2-Complete melting, mixing, homogenization, and reaction in the twin-screw extruder.

3-Finish cooling and extrusion in the single-screw extruder, by pelletizing.

4-Pack the pellets after being water-cooled, dehydrated, dried, and stored.

| Model | Screw Diameter(mm) | Max.screw speed(rpm) | L/D | Motor Power(kW) | Throughput(TPU example)kg/h |

| SK63 | 63 | 900 | 40-48 | 250 | 500-1000 |

| SK73 | 73 | 900 | 40-48 | 400 | 800-1800 |

Loss-in-weight feeding system

-Principle-

The feeding electric vibrator is softly connected to the hopper for gravity separation. Although the discharging electric vibrator is also soft connected, its gravity and hopper are supported by tension sensitive sensors. The feeding electric vibrator firstly feeds to hopper, and when the weight in hopper reaches the set limit, the feeding stops. Next, the discharging electric vibrator starts, and when the discharging reaches the given weight limit, it stops. The material flow rate is measured by the weight of the material lost from the hopper.

-Advantages-

1.No material layering: Physical layering will not occur during transportation due to differences in material characteristics.

2.Highly automated: a touch screen is all you need .

3. Precise formula feeding: Input formula proportions into the settings.

4. Efficient and stable product quality: Accuracy error is less than 0.5%, enabling stable product quality.

5. Low labor cost: One person can operate the entire production system.

6. PLC control system significantly reduces labor intensity.

7. High performance, low energy consumption: High-torque motors fully meet the transportation requirements for various materials.

-Technical Indicators and Functions of the Loss-in-Weight Feeding System-

1.System measurement accuracy: ≤ ± 0.5%.

2.Computer power supply: 220V+10%; 50Hz, 500mA.

3.Proportioning and measurement of multiple materials: Customization of models and measurement can be based on each type of material.

4.Manually input the content of materials and automatically calculate the proportion of each type of material.

5.Equipped with automatic signal input interfaces for multi-element analysis.

6.Data protection: The built-in battery saves the clock and all data in the event of a power outage.

7.Equipped with a communication interface, it can be connected to the central control room management computer to form a network. According to work requirements, it can be remotely connected and communicated.