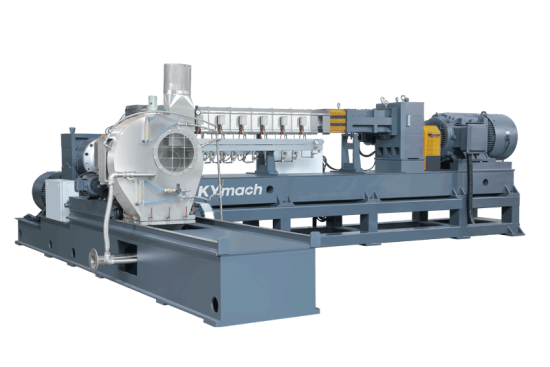

For Heat-Sensitive Materials

Tailored for heat-sensitive materials modification, blending, and pelletizing. Suitable for processing PVC, XLPE, soft and rigid PVC, EVA, PE, carbon black masterbatch and more. The twin-screw system allows non-back-pressure melt to enter the single-screw extruder for efficient pelletizing, supporting various pelletizing methods including air-cooling, eccentric water-ring, strand, and water-ring pelletizers.

| Twin screw extruder(The first stage) |

|||||

| Screw diameter(mm) | 53 | 63 | 73 | 96 | |

| Max. Screw speed(rpm) | 600 | 600 | 600 | 600 | |

| Main motor power(kW) | 90 | 200 | 315 | 630 | |

| Single screw extruder(The second stage) | |||||

| Screw diameter(mm) | 120 | 150 | 180 | 200 | 250 |

| Max. Screw speed(rpm) | 90 | 90 | 90 | 90 | 90 |

| Main motor power(kW) | 37 | 35 | 90 | 110 | 160 |

| Throught(gk/h) | 100-500 | 150-900 | 300-1500 | 600-2000 | 800-3000 |

XLPE cable materials, PVC cable materials, shoe sole materials, transparent plastics, medical-grade materials, low-smoke halogen-free or halogen-free flame-retardant cable materials, EVA shielding materials, PE/EVA carbon black masterbatches, and etc.