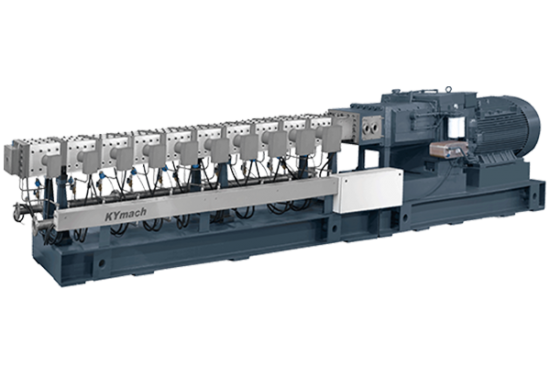

Optimized for Polymerization & Devolatilization

Ideal for reactive polymerization, devolatilization, food, and pharmaceutical applications. Incorporates deeper grooves and a 35% larger volume screw to reduce shear force, extend material residence time and enhance polymerization. The Do/Di ratio of 1.8 enables faster screw speeds and higher output, with efficient devolatilization through larger screw volume and lower vacuum air speeds.

| Model | unit | HKV 54 | HKV 77 | HKV 100 | HKV 140 | HKV 190 |

| Screw diameter | mm | 54 | 77 | 100 | 140 | 190 |

| Max. screw speed | rpm | 150/300 | 150/300 | 150/300 | 150/300 | 150/300 |

| Main motor power | kW | 22/45 | 55/110 | 90/200 | 250/450 | 450/900 |

| L/D | Max | 68 | 68 | 68 | 68 | 68 |

| Throughput | kg/h | 100-200 | 300-500 | 600-1000 | 1500-2500 | 3000-4500 |

*The main motor power varies with the process

Polyaramid polymerization, polyaramid spinning, continuous silicone polymerization, continuous high-temperature nylon polymerization reactions, and devolatilization processes.

Potential application fields include filling thermoplastics, polymer devolatilization, continuous bulk or solution polymerization, powder coatings, food processing, pharmaceuticals, sealants, pet food processing, as well as mixing, dissolving, and evaporation.