Twin-screw extruders are widely used for devolatilization in various polymers and rubbers.

Advantages of twin-screw extruders in devolatilization:

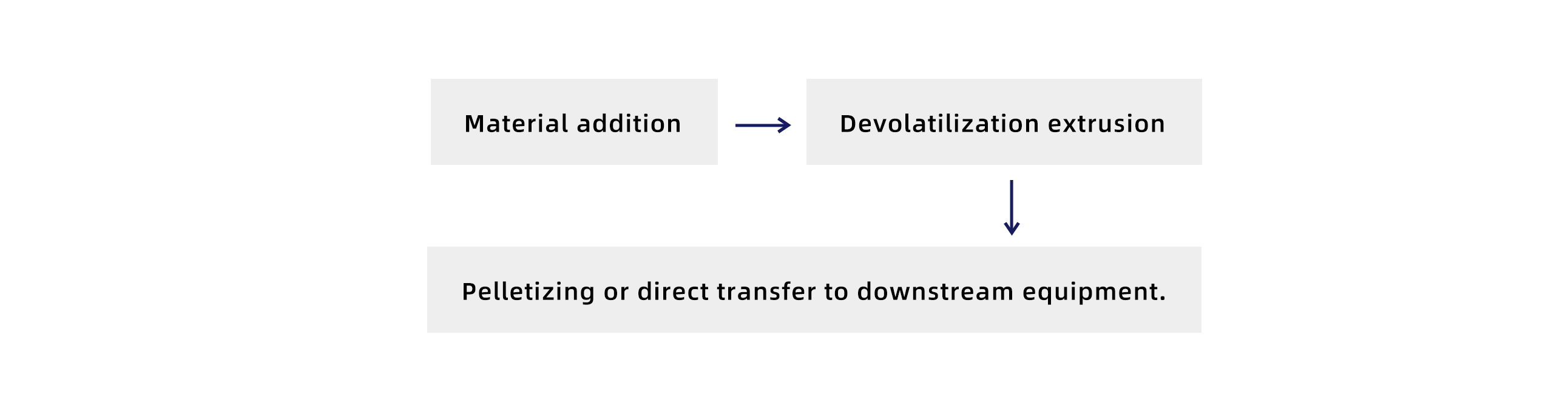

1. The devolatilization process in twin-screw extruders is a continuous process.

2. Efficient heating and precise temperature control enable thermal balancing and heat evaporation

3. High devolatilization efficiency, with continuous surface renewal during screw rotation, accelerates evaporation.

4. Modular design provides flexibility and allows for precise devolatilization with multi-stage vacuum ports at varying vacuum levels and air speeds.

-For polymers-

Solvent removal, Dehydration, Monomer removal, Byproduct removal

-For rubber-

Solvent removal, Dehydration

| Model | Screw Diameter(mm) | Screw Speed(rpm) | L/D | Motor Power(kW) | Throughput(kg/h) |

| HKV54 | 54 | 150/300 | 68 | 22/45 | 500-100 |

| HKV77 | 77 | 150/300 | 68 | 55/110 | 150-250 |

| HKV100 | 100 | 150/300 | 68 | 90/200 | 300-500 |

| HKV140 | 140 | 150/300 | 68 | 250/450 | 750-1200 |

| HKV189 | 189 | 150/300 | 68 | 450/900 | 1500-2000 |