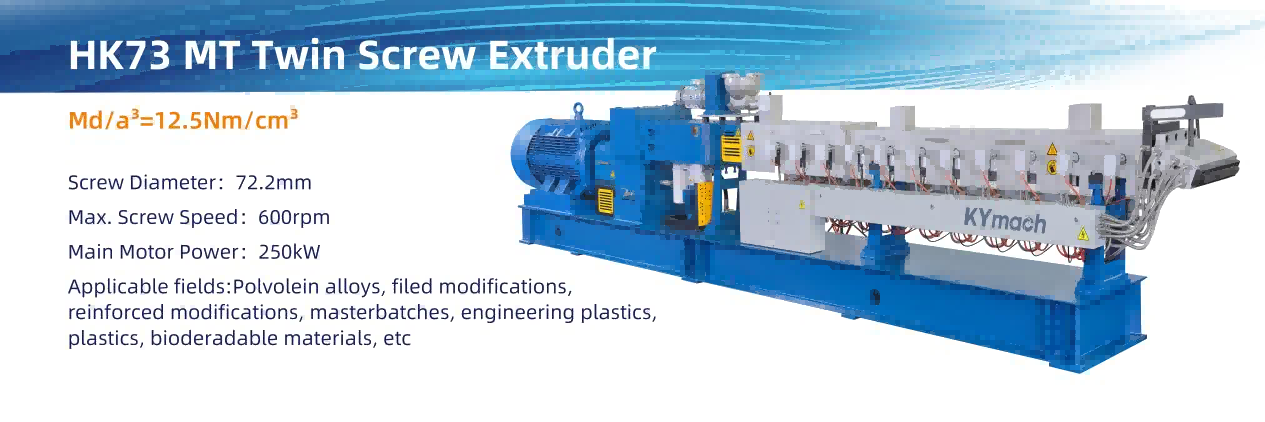

On March 11, 2025, KYMACH made its debut at PLASTIMAGEN MEXICO, showcasing its exhibition machine. This marked a significant milestone in the company's efforts to expand into overseas markets. At the exhibition, KYMACH presented the HK 73 MT twin-screw extruder, specifically designed for international markets. This equipment is specially designed for high-filled and reinforced modified plastics, making it ideal for processing materials such as nylon + short glass fiber and PP + talc powder.

Key features:

1.High Torque Gearbox:

With a torque density of up to 12.5 Nm/cm³ and a stable torque output of 2506 N·m, this gearbox ensures reliable operation even under high-load conditions. It's especially suitable for processing high-viscosity, highly filled materials like nylon + short glass fiber and PP + talc powder.

2.High Wear-Resistant Barrel and Screw Design:

To tackle the high wear characteristics of nylon and short glass fiber, the extruder is equipped with KYmach’s patented AD-02 nickel-based powder alloy sintered barrel, which offers 1-2 times the wear resistance and 2-4 times the corrosion resistance of standard barrels. This significantly extends the equipment's lifespan.

3.Optimized Screw Design:

The specially designed screws effectively disperse short glass fiber, preventing over-shear and breakage, enabling uniform fiber distribution and meeting customers’ demands for high-quality modified plastics.

4.Efficient Temperature Control System:

Paired with advanced cooling channel design and Italian CEME brand solenoid valves to maintain stable melt temperature. This prevents material degradation and ensures consistent product quality.

5.Modular Design:

The screw combination is modular, allowing for flexible combinations based on different processing needs. This enhances the extruder’s adaptability to a variety of complex filled and reinforced material formulations.

6.Digital Support to Boost Global Competitiveness:

KYmach is not only innovating in hardware but also actively exploring digitalization. Through smart, automated solutions, we help our customers gain an edge in the global market.

6.1 Remote Monitoring and Real-Time Diagnostics: Customers can monitor equipment status in real-time through the cloud platform, access detailed data analysis reports, and perform remote troubleshooting and optimization to enable continuous, efficient operation.

6.2 Automated Control System: The PLC control system automatically adjusts processing parameters, ensuring product stability and consistency for every batch and reducing human error.

6.3 Improved Production Efficiency: By using mega data analytics, we help customers optimize production line setups, improve equipment efficiency, and reduce energy consumption by 15%, thus lowering operating costs.

The equipment showcased at PLASTIMAGEN MEXICO has already been successfully acquired by a well-known masterbatch group in Mexico. It plays a key role in improving their production efficiency and product quality. A picture of the customer’s factory is included in this article.

Looking ahead, KYmach will continue to help customers achieve higher efficiency and better-quality products in the global market.

From NPE to PLASTIMAGEN MEXICO: How KYMACH Conquers the International Market

Mar 12. 2025

From NPE to PLASTIMAGEN MEXICO: How KYMACH Conquers the International Market

Mar 12. 2025

Continual Innovation and Steadfast Tradition

Dec 19. 2024

Continual Innovation and Steadfast Tradition

Dec 19. 2024

KY Elected as a Council Member of the Cable Materials Special Committee

Nov 22. 2024

KY Elected as a Council Member of the Cable Materials Special Committee

Nov 22. 2024

Ceremony of “China Plastic Machinery- KYmach GUANGZHI Award”

Aug 10. 2024

Ceremony of “China Plastic Machinery- KYmach GUANGZHI Award”

Aug 10. 2024